Yet again, below is a case study on an incident with fatality happened in Spore.

It is relevant to our lifting operations; pls read on the lesson learnt and some recommendations.

Case Study - Source: WSHC Portal

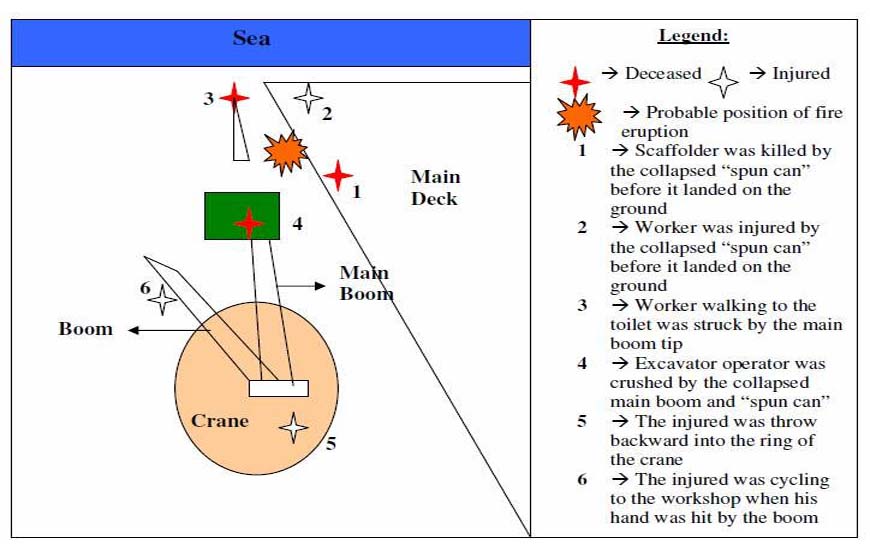

The incident happened in April 2006, during the lifting of a 182 ton load, the crane suddenly collapsed, taking 3 workers’ lives instantly and injuring 3 others.

Summary of Events

On the incident day, at about 0900 hrs, the lifting of an approximately 182 ton “spun can” (a movable structure or a “shoe” that is connected to the leg of an oil rig) by a crawler ringer crane commenced. The mission was to lift the load from the ground and to place it into the forward leg well of the oil rig which was still under construction.

The crane operator lifted the load and slewed the boom of the crane gradually to about 45 degree to his right and held the load at about 4 metres above the main deck of the oil rig. During the lifting process, one of the 3 tag lines that served as a guide rope to control the swaying movement of the lifted load came into contact with the scaffolds that were erected next to the oil rig. A rigger managed to clear the tag line from the scaffold.

After the tag line was cleared from the scaffold, the operator continued to slew the boom slowly toward the forward leg well, within the designated working radius of 30 metres. The same tag line once again came into contact with the scaffold and had to be cleared again by the rigger before operation could continue.

During the lifting operation, other shipyard activities went on as usual. Scaffolders and workers on the main deck resumed their work once the load had been lifted a distance away from their working area. Other workers and vehicles were free to move within the lifting zone and an excavator was moving around the vicinity during the lifting operation.

At about 0915hrs, during the slewing of the boom, the operators experienced a resistance that prevented the boom from being slewed any further. Attempts were made to slew the boom by progressively easing back and powering up the boom.

At about 0935hrs, after operator had rotated the boom by 90 degrees, he held it there within the designated operating radius of 30 metres. The operator heard a “metallic cracking sound”, and the boom collapsed to the ground. This caused the “spun can” that was being lifted to fall onto the main deck of the oil rig and subsequently fall onto the collapsed boom on the ground.

As the crane collapsed, the “spun can” struck some gas cylinders within the lifting zone which resulted in a fire.

3 workers were killed instantly and 3 other workers were injured as a result of the collapsed.

- A scaffolder who was staging materials on the main deck was killed instantly after being struck by the “spun can”.

- An operator of the excavator was crushed and killed after being struck by the collapsed boom and “spun can”.

- A worker walking toward the toilet was killed after being struck by the collapsed boom tip.

- A worker was injured by the fallen “spun can” while aligning some of the measurement on the main deck.

- A worker cycling to the workshop was struck by the collapsed boom and fractured his left arm.

- Lastly, a worker who was ensuring that the load did not swivel during the lifting operation was thrown backward into the ring of the crane and was injured.

Lessons Learnt

- Collapse of crane: not another dangerous occurrence but a fatal incident

- Usage of wire ropes: Wire ropes that do not comply with the mandatory statutory requirement of annual examination and test by authorized examiner should not be used.

- Ground compaction: Special attention should be taken when the mobile crawler crane is used to further compact the ground. There should be additional measures to ensure that the ground is safe for the crane to travel without facing the risk of collapsing. One such measure would be placing adequate steel plates over the ground to prevent the collapse of crane if the ground is still soft.

- Proper planning of site: Proper planning of site should be carried out prior to the start of work. This is to ensure that surrounding obstructions is brought down to the minimum during lifting operation or any other operation.

Recommendations

- Adequate knowledge through training: It is important for the workers to have adequate knowledge in handling different work situations and emergencies in order to reduce the risks involved. Management should provide workers with the necessary training.

- Safety Culture: Management should endeavour to inculcate appropriate safety culture into the mindset of workers to reduce the probability of workers putting their (and their co-workers’) lives in danger.

- Check on the level of the crane: The ground condition in which the crane is placed is crucial to the stability of the crane. Significant change in the angle will lead to catastrophic events. Hence Management should ensure that the crane is levelled within the tolerance limit, throughout the lifting operation. Else measure should be taken.

- Strict supervision: Management should provide strict supervision during lifting operation and not to condone any bad practices. All works in the lifting zone during lifting operation must be stopped without exception.

- Risk assessment and Safe Work Procedure: Risk assessment should be carried out prior to start of any work in order to identify potential hazards so as to eliminate or reduce the risk involved. This could be done by having a safe work procedure to help the workers to handle the hazard and to work safely.

- Barricade for lifting zone and communication of lifting operations: In addition to verbal instructions, physical barricade should be installed to prevent unauthorized personnel or vehicles from entering into the lifting zone during lifting operation.

- Commencement of lifting operations should also be communicated clearly to the affected workers.

- Safety Management System: Effective safety management system and comprehensive record keeping will help to reduce the probability and severity of incidents from happening.

- Maintenance of equipment: The condition of the equipment also plays a crucial role in assessing the reliability of the equipment. Management should ensure that equipments used are properly maintenance with good record keeping.